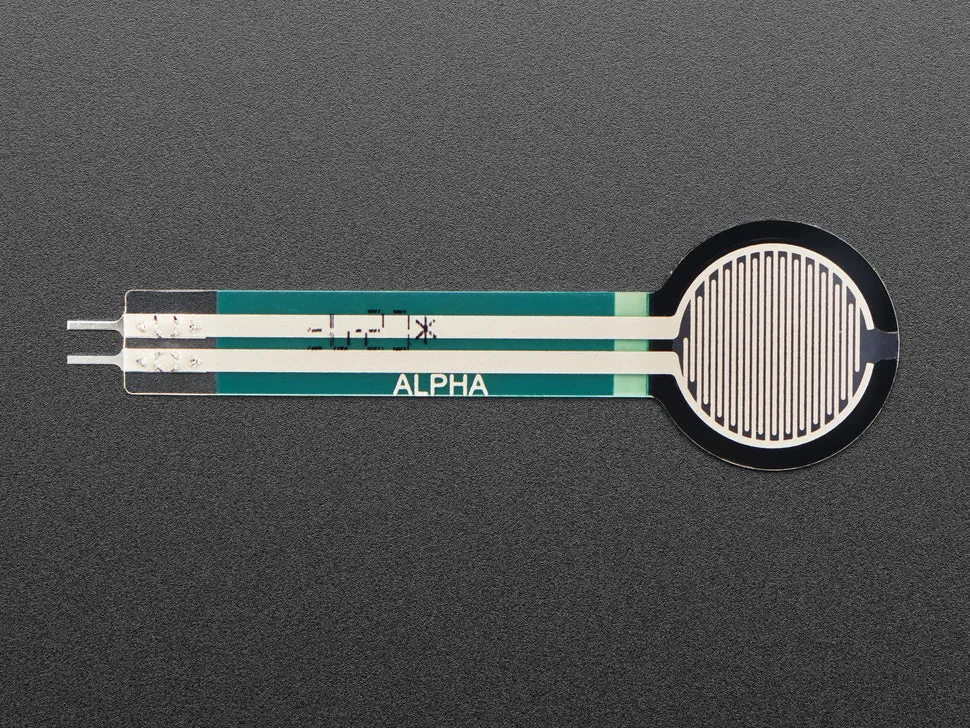

An FSR is a sensor that responds to pressure, squeezing, and weight. This type of resistor changes its resistive value (in ohms Ω) depending on the amount of pressure applied. FSRs are cost-effective and easy to use, though accuracy often varies from device to device by up to 10%. As such, the data obtained from FSRs should be treated as a range of response, rather than an exact measure. FSRs are not recommended for precisely measuring the amount of weight applied.

, but is less sensitive - which means its great for stronger force measurements: up to 100 Newtons! This makes it better for when the pressure applied is stronger and you want the analog measurement range to go higher.

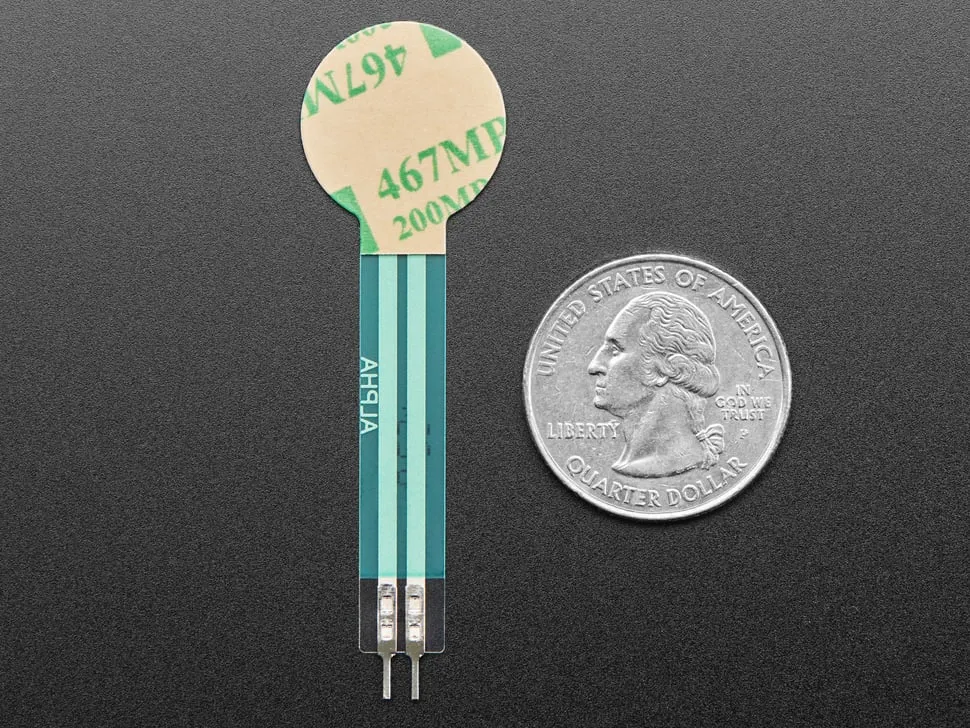

FSRs are made of plastic and the connection tab is crimped on delicate material. The best way to connect to these is to simply plug them into a breadboard or use a clamp-style connector like alligator clips, female header, or a terminal block. It is possible to solder onto the tabs but you must be very fast because if your iron is not good quality or you dally even a few seconds, you will melt the plastic and ruin the FSR! Don't attempt to solder directly to your FSR unless you are absolutely sure you have the skills to do so.

For a full tutorial with wiring diagrams, code examples and project ideas, please !

Technical Details

Dimensions:

- Length:: 60.4mm/2.37in

- Width: 18.33mm/0.72in

- Thickness: 0.56mm/0.02in

- Weight: 0.9g/0.03oz

Specifications:

- Force sensitivity range: 100g~10,000g (1N~ 98N)

- Force Resolution: Continuous (Analog)

- Stand-off / Open unloaded resistance: >20MΩ

- Force repeatability (single part) 2%

- Force repeatability (part to part) 10% within a single batch

- Response time: <1ms

- Life cycle (without failure): > 5 Million

- Operating temperature: -30°C to 85°C